What is APQP?

What is Advanced Product Quality Planning?

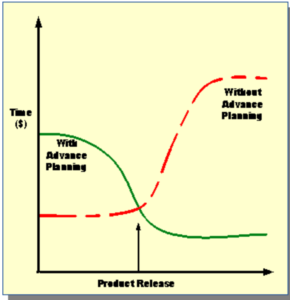

APQP stands for Advanced Product Quality Planning. It is a disciplined process for suppliers to ensure they are capable of designing product and/or manufacturing systems that will meet their automotive customers’ requirements. It outlines a process for introduction of a new product while minimizing risk for you and your customer.

Learn More about APQP with this Tutorial:

Buy a copy of AIAG Standards:

- APQP-3 (2024) – Advanced Product Quality Planning and Control Plan

- IAQG Core Tools Manuals – Core Tool Requirements 6-Pack APQP, PPAP, FMEA, etc.